CS OMNIWALL BEDHEAD

The CS Omniwall Bedhead system is an innovative integrated bedhead wall system that provides fast and clean delivery of bedhead services within healthcare environments. Designed with build efficiency in mind it is suitable for fast track new and refurbishment projects.

WHO WE ARE

The Omniwall Bedhead System is the result of a collaboration between two market leading companies with many years experience offering innovative and cost effective solutions to the healthcare market.

CS is a global manufacturer and supplier of a range of specialist building products including partition systems, wall protection systems, entrance matting systems, specialist coatings for walls and floors, expansion joint covers, solar shading, louvres, cubicle curtain track and pressure relief systems.

Static Systems specialise in providing both ‘wired’ and ‘wireless’ nurse call solutions that are cost-competitive, fit-for-purpose and built to last. Their solutions are innovative and market-leading; concentrating on delivering improved patient safety, patient experience and workflow efficiency.

THE SYSTEM

Designed and manufactured off-site to project specific dimensions and functional requirements, the system is delivered pre-cut, pre-finished and palletised for easy, clean and snag-free assembly on-site.

1.

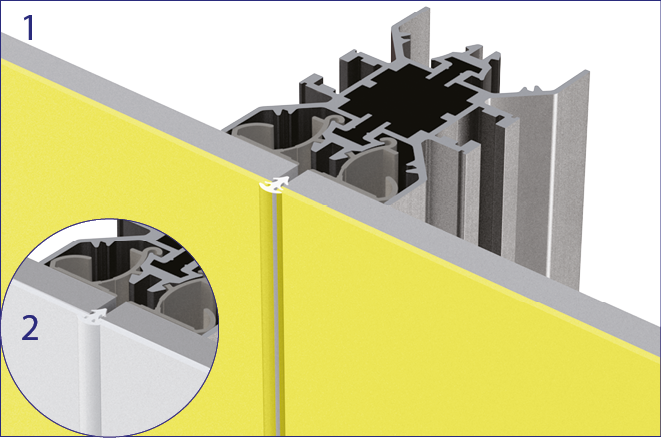

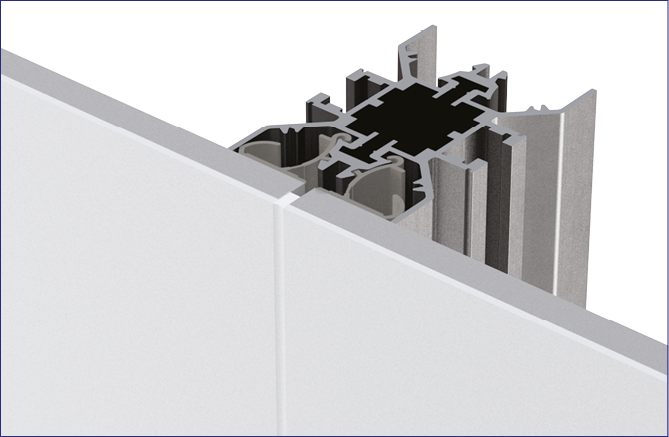

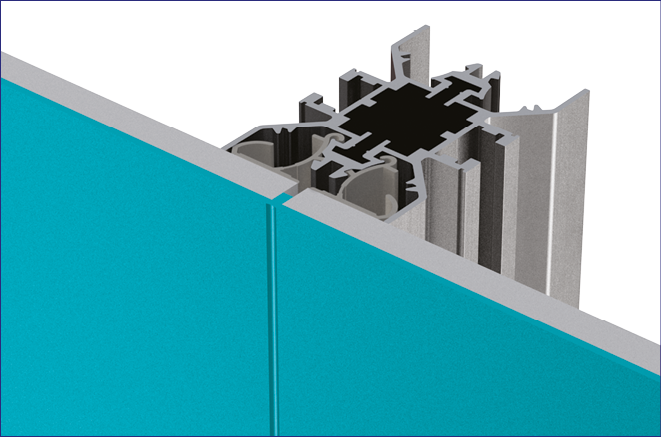

SYSTEM CHASSIS

2.

BEDHEAD SERVICES

3.

PANEL FINISHES

4.

JOINT OPTIONS

See how the system is built

Designed for the Healthcare Environment

- Attractive, flush space saving design available in two variants, to enhance the patient environment

- Wide range of finish options to suit functional and aesthetic project requirements; including printed graphics

- Easily cleanable and maintainable hygienic finish to meet infection control needs

- Overall dimensions meet ProCure 22 Repeatable Rooms design layouts.

Integrated Services & Equipment

As standard the Omniwall Bedhead comes with a Static Systems Bedhead Trunking system designed to be delivered fully assembled, ready for installation within the Omniwall Bedhead offering a flush finish.

- Integrated bedhead services console, designed for recess fitting into the CS Omniwall Bedhead system framework for flush finish

- Smooth profile to minimise entrapment of dust and build-up of bacteria (IP 54)

- Innovative design, supplied pre-built for ease of installation and servicing

- Quality build with segregated compartments for ELV, LV and piped services

- Easy removal of front plate for access to services

- Accommodates any combination and type of gas outlet, medical, electrical and communications equipment

- All services are installed, tested and certified in line with current standards to facilitate fast and easy connection

Omniwall Bedhead can also be supplied pre-piped and pre-wired for easy connection to plumbing and electrics on site, helping to reduce install time, labour costs and wastage.

Quality Build

- Consistent quality, fit and finish the CS Omniwall Bedhead system is manufactured in a controlled factory setting

- Robust framework combining steel and aluminium components

- Wall panels comprise Class A1 fire rated, moisture resistant MgO board, pre-finished with an impact resistant, hygienic Acrovyn Sheet.

- Modular construction, easily scalable and adaptable, suitable to create the entire ward walling where required

- Tested to BS 5234-2:1992 – click to view testing information

Fast & Clean Installation

- Delivered in easy to handle sections, pre-cut to required dimensions, pre-finished, and pre-fitted with clips, the system is delivered to site flat packed with little or no snagging required.

- Installation is carried out quickly and efficiently, without the involvement of multiple trades.

- Faster to install than traditional wall construction solutions causing less disruption to existing operations, with better control of project delivery scheduling and budgeting

Easy Maintenance

- Easy to remove panels allowing access to services in the wall cavity

- Panels can be quickly swapped without the need for specialist contractors

- Modular construction provides scalable, adaptable and flexible configuration to suit available spaces and functional requirements throughout the life-time of the building

Improved Health & Safety

- Pre-cut and pre-finished panels means that the system just needs to be assembled on site, reducing the use of power tools and length of time working at heights

OMNIWALL Panel Finishes

Our standard Acrovyn wall panel finishes have been specified in healthcare environments for decades, and are well known for their durability and resistance to impact damage and wear & tear. Laminated to the rigid MgO board substrate, Acrovyn faced panels provide a highly robust wall finish, designed to stand up to the demands of busy hospital interiors. Acrovyn facings effectively mask scratches or abrasions, and can be cleaned repeatedly with soapy water, or commonly used disinfectant cleaning agents.

Acrovyn®

Tried and tested in healthcare facilities for over 40 years, 2mm Acrovyn sheet provides an impact resistant and easily cleanable surface finish.

Acrovyn® Hydroclad

Designed for hygienic areas and cleanrooms, 2mm thick Acrovyn Hydroclad provides a smooth and matt wall panel finish, which is very easy to clean.

Acrovyn® 4000

1.5mm thick, PVC-free version of our Acrovyn Sheet delivers comparable performance, has a contemporary, shallow texture, and is easy to keep clean.

Acrovyn by Design

CS’ bespoke wall panels help to create healing hospital interiors. Acrovyn by Design is printed on the back of clear Acrovyn Sheet for a durable, wipe clean surface.

Panels will be stocked in 1.5mm Acrovyn 4000 in Mission White, should you require a different colour or finish option, please discuss it with the design team as they may be subject to longer lead time and additional costs.

OMNIWALL Vertical Joint Options

To assist with infection control, and seal gaps between panels, we offer a range of different options to suit your requirements. For future flexibility and ease of maintenance we recommend the gasketed option, as it gives you the freedom to re-configure in the future, or get behind the panel for maintenance, without compromising the panel finishes.

Gasket

A simple, push-in gasket for a neat vertical joint finish. Suitable for most hospital areas and available in Clear (1) or White (2) as standard.

Mastic

Easy to apply, colour-matched mastic creates a flush surface finish and is suitable for most hospital areas.

Hot Weld

Durable solution for areas requiring a seamless joint detail. Available with Acrovyn or Acrovyn Hydroclad wall panels; colour-matched.

OMNIWALL Standard Specification

CS Omniwall System

- Overall size*: Width: 3,500mm – 4,500mm

- Height: 2,800mm floor to ceiling

- Configuration*: 3 full 1,150mm panels + infill panels to suit

- Panel finish*: Material: PVC Free, Acrovyn 4000 Sheet

- Texture: Suede

- Colour: Mission White 993

- Panel core*: MgO board, A1 Class fire rated, moisture resistant

- Joint options: Mission White 993 Gasket as standard, colour matched mastic or hot weld optional

- Framework: Aluminium & steel components

- Installation: All metal components delivered cut to size. All panels pre-finished. Full panels pre-cut to size with fitting clips attached; infill panels to be cut onsite for a perfect fit

* Other sizes, configurations and panel finishes/colours can be supplied to order

Static Systems Bedhead Services Console

- Size: 1350mm (H) x 600mm (W)

- Cable capacity: Approx. 1100mm2 (per compartment)

- Pipe capacity: 6 x 15mm with outlets mounted in 2 rows*

- Cable & pipe entry: Top and rear

- Weight: Approx. 40kg (depending on components)

- Finish: Powder coated to ‘white’ RAL 9010, 25% gloss (matt)**

- Materials: Extrusions – Aluminium EN AW 6060 T66

Frontplates – Steel (1.5mm)

Divider strips – PVC, ‘white’ RAL 9010

Plastics – ABS, ‘white’ RAL 9010 - Mounting: Recessed within CS Omniwall Bedhead framework for a flush finish

* Alternative widths and configurations can be accommodated

** Alternative RAL colour finishes available to special order

OMNIWALL Testing Information

CS Omniwall has been tested to BS 5234-1992 – Partition (Including Matching Linings) – Part 2: Specification for Performance Requirements for Strength & Robustness Including Methods of Test and achieved the below results:

3 kN/m

[Resistance to Crowd Pressure Test]

Severe Duty

[Determination of Partition Stiffness]

[Soft Body Impact Testing]

[Hard Body Impact Testing – Surface Damage]

[Soft Body Impact Testing – Junction Damage]

[Hard Body Impact Testing – Perforation]